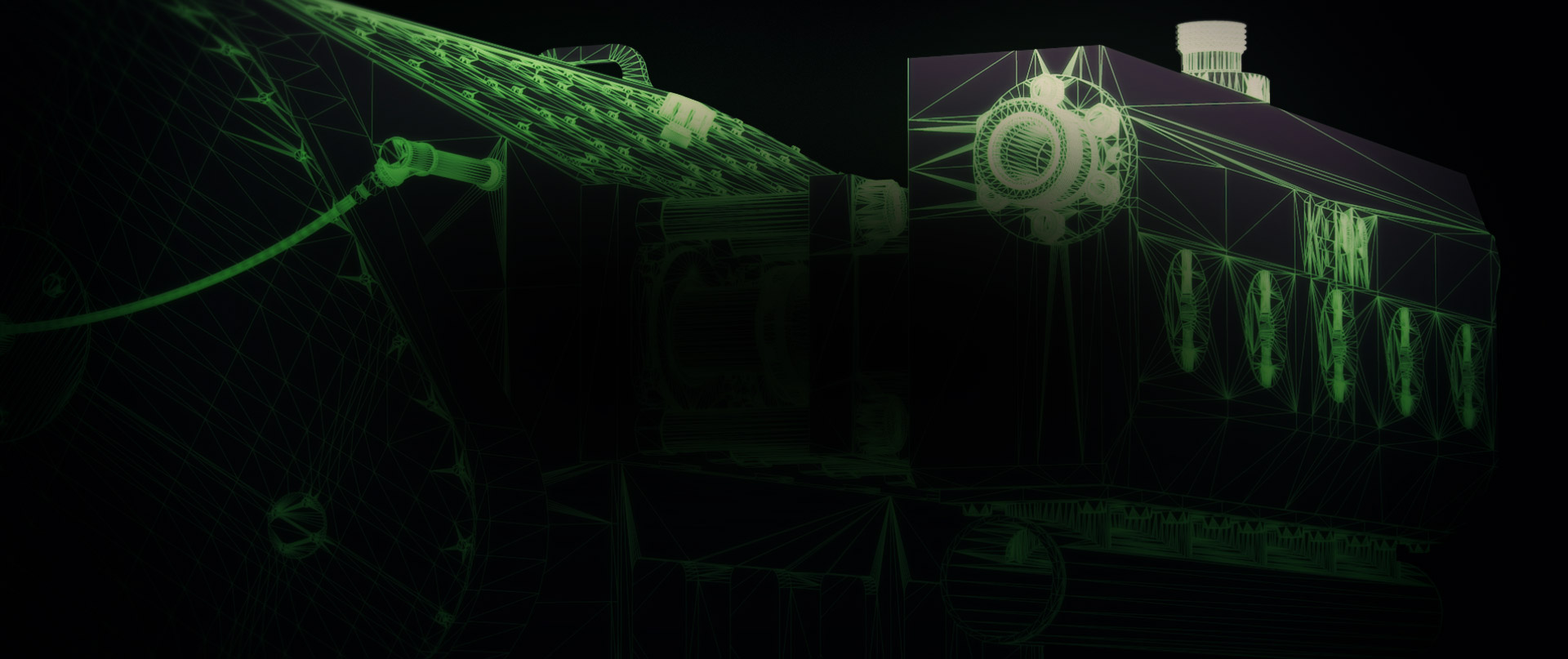

More Machines Than You Can Count.

Our CNC machining facility is simply state of the art. Our machine arsenal includes: live tooling lathes, 5-axis boring mills, vertical machining centers and horizontal machining centers. Our plant is so equipped that it is the largest machining company in all of Oklahoma.

Kerr Production System

Our production system is a melting pot of manufacturing methods. We have implemented improvement tools such as Lean, 5S, Kaizen, TOC and TQM. The biggest tool that we use is the creativity of the human mind. We are always dreaming up ways to improve processes that better our system.

ISO 9001: 2015 Certified

We meet and exceed the requirements stated in the ISO 9001: 2015 quality manual. Our obsessive focus on quality begins where the part is made and continues long after it is delivered to the customer. This intense dedication is the reason why we are the gold standard in pump quality.

One Roof One Vision

Everything at Kerr Pumps is designed, engineered, machined, assembled and tested under one roof. This allows us to communicate effectively across the entire company which improves collaboration, problem solving and response time. No other pump company in the world has this advantage.

Engineering Experience

Our continuous search for the best materials, processes and designs is coupled with a focus on constant improvement. Our engineers apply their experience and expertise with solid modeling and finite element analysis, resulting in a unique solution for an array of markets and customers.

Talented Team

Kerr Pumps has some of the best talent in the entire pump industry. Our goal is to hire the brightest people and give them the biggest challenges to produce the best work of their lives. These driven individuals work collectively to manufacture high quality pumps at unbelievable lead times.

Apply Now