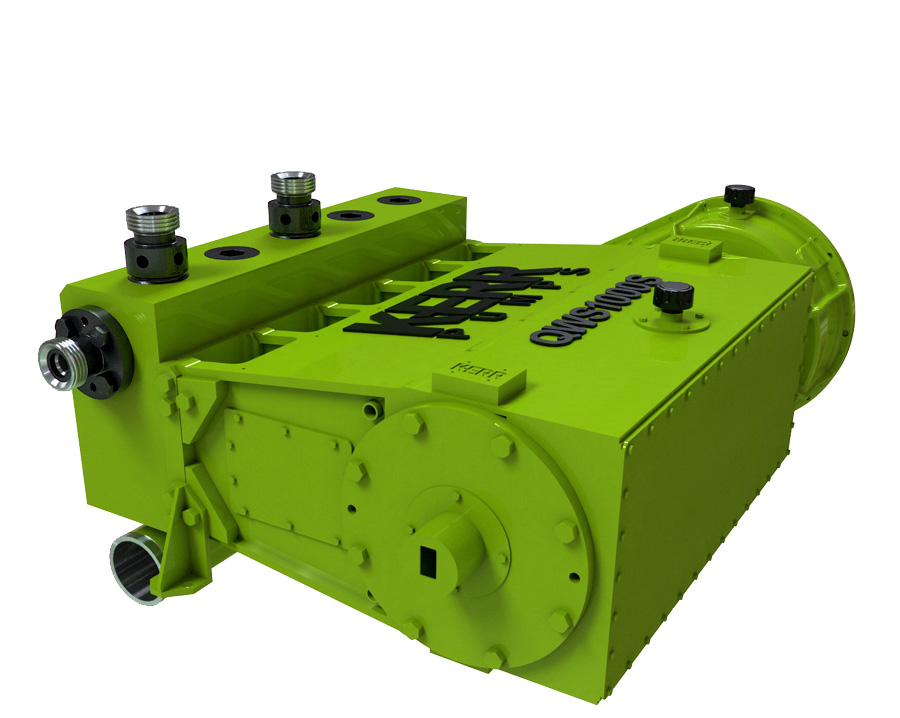

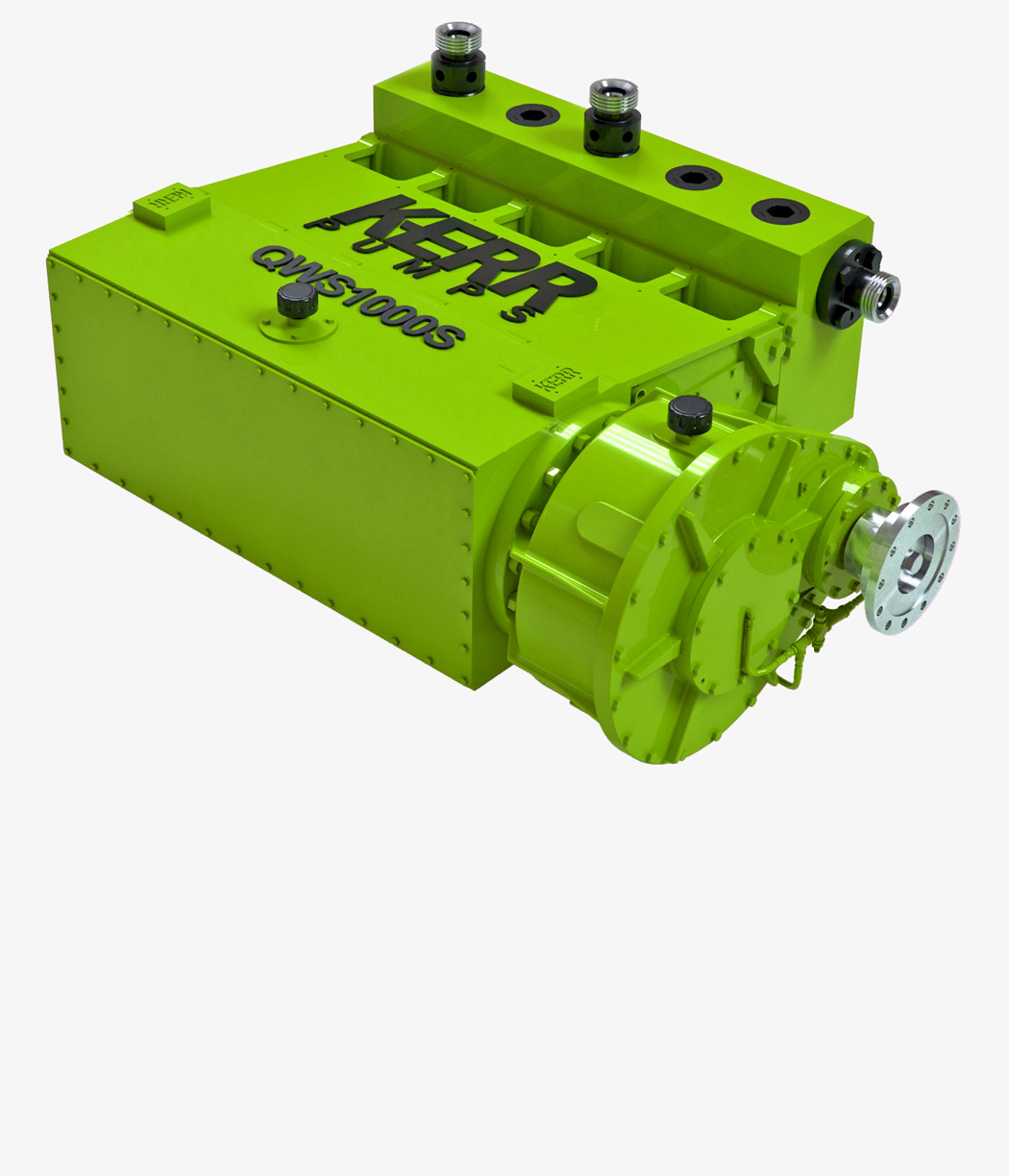

Interchangeable Design

Each fluid end has removable stuffing box adapter rings designed to fit other OEM power ends. End bolt patterns are also available in either small bolt (1”-12 UNF) or big bolt (1 3/8”-12 UNF). We are certain that Kerr Pumps fluid ends will be a great fit for your pumping needs.

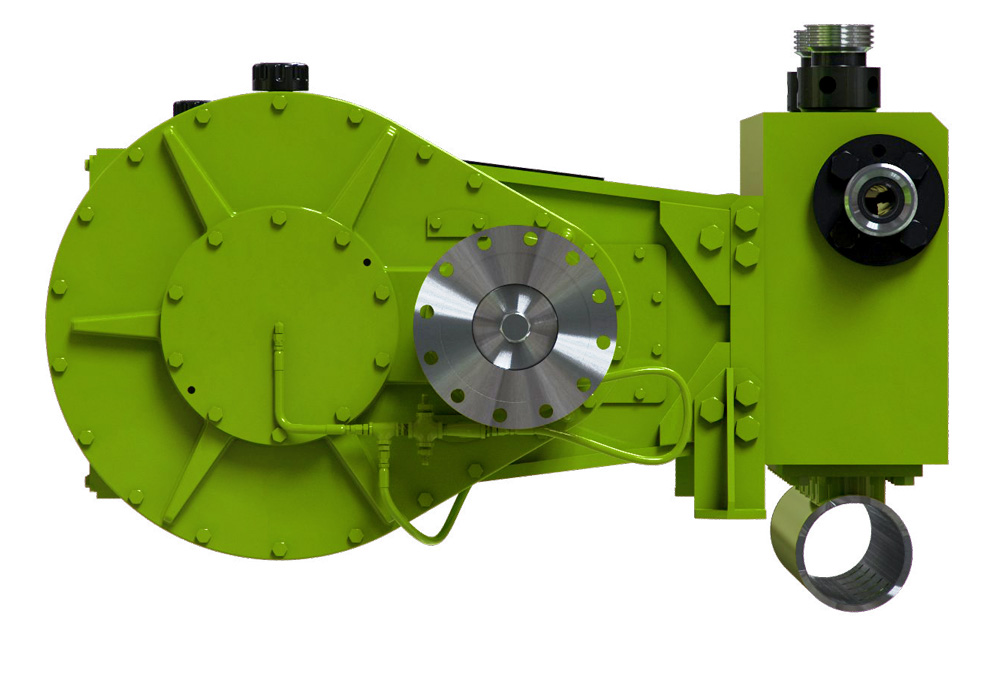

Torqued Up!

Our fluid end bolts are 12 point, high torque type with percent load gauges. This high tech bolting technology helps evenly set the engineered torque level that is required for assembly. The load gauges also enable you to easily maintain the perfect torque for safe and reliable field performance.

Go together, Right now.

Our power frames are made to fit with other OEM fluid ends. Each quintuplex power frame fluid end plate is drilled and tapped for both small and big bolt configurations. This unique design advantage gives you more flexibility in the field when you need to replace your fluid ends.